SIEVES > TTA Spillway Screens

INTRODUCTION:

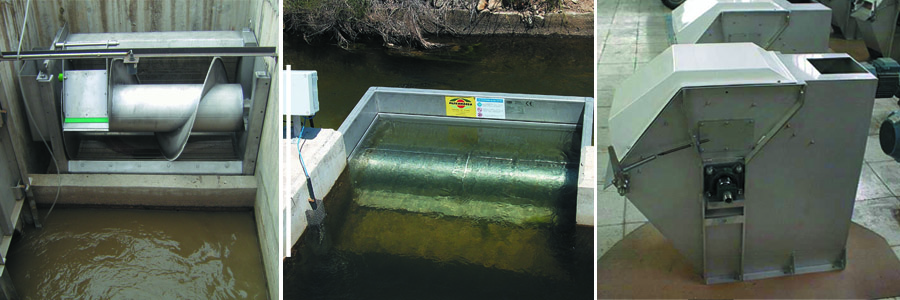

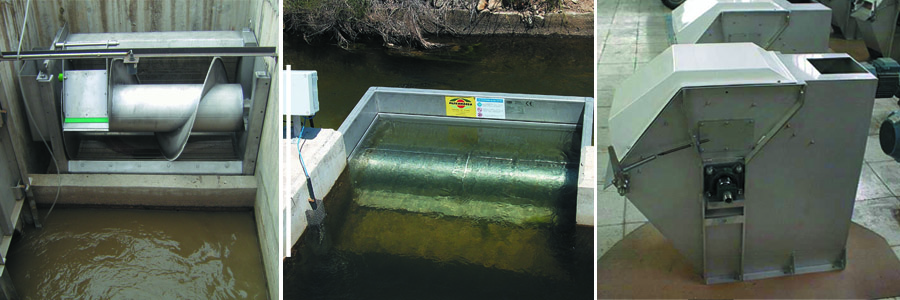

Spillway sieves are placed in the side spillways of the collectors to prevent solids from escaping into the river bed.

The TTA sieve is simple to operate: When the collector’s water level reaches the discharge threshold, a level buoy is activated to give the TTA the command to start the operation. An oil-hydraulic group, located in a place isolated from the effects of water, starts up a hydraulic gearmotor designed to work underwater, a screw conveyor with a nylon helicoidal brush attached to its edge. The screw transports the solids retained in the filter element downstream and simultaneously cleans it continuously.

When the solids reach the end of the screw, they are reincorporated into the collector channel by means of a pivoting scraper/blade system. In this way, a filtered water free of rags and other unpleasant solids is poured into the public waterway, which is taken by the collector back to the treatment plant or pumping station, at which time the solids are extracted into the container by sieves or clean-up equipment.

DESCRIPTION:

The TTA spillway sieve is a very good solution for both new and existing installations where it cannot otherwise be installed or where there are hydraulic restrictions upstream. In addition, as these equipments are usually installed in places that are difficult to access or that do not have a place for the extraction of the waste, they are ideal since the waste is returned to the collector or arrival channel for its later treatment in the WWTP. The two-dimensional dimensional clearance of the perforated plate ensures high solids retention.

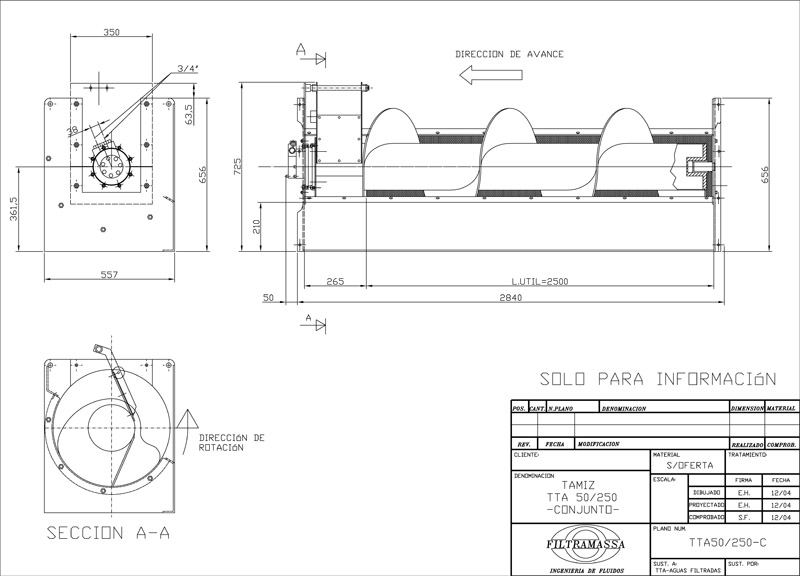

The self-propelled TTA spillway sieve is placed horizontally in the inlet manifolds in front of the side dump. It consists of a half-round perforated plate, with an arc of 180º, which acts as a filtering mesh and a conveyor screw that turns concentrically to it. The mesh is cleaned by means of an adjustable, wear-resistant brush mounted on the edge of the worm.

The equipment operates fully automatically during rainfall events. The drive is carried out by a device that transmits the force of the water directly to the gearmotor.

The TTA spillway sieve has the following FEATURES:

- Dimensioned light, 3-6 mm in perforated plate.

- Installation in side landfills and storm tanks.

- Very robust and low maintenance equipment.

- Fully automated continuous cleaning of the filter screen.

- Efficient separation and removal of suspended and floating solids.

- Treatment of large flows even in installations with upstream hydraulic restrictions.

- The waste is returned to the channel or collector for subsequent treatment in the plant.

- Self-propelled equipment, no electricity required.

-

Maximum flexibility when it comes to installing it both in new buildings and in existing installations.

GENERAL DIMENSIONS:

|

CLIENTE / CUSTOMER |

CANT./QTY |

PROYECTO / PROJECT |

| ABENSUR |

1 |

Edar Brea de Tajo |

| ABENSUR |

1 |

Edar Estremera |

| ABENSUR |

1 |

Edar Villamanrique de Tajo |

| ABENSUR |

1 |

Edar Fuentidueña de Tajo |

| ABENSUR |

1 |

Edar Villarejo de Salvanés |

| AGUAS FILTRADAS |

2 |

Aliviadero Alcalá |

| ALDESA |

1 |

Ampliación Parque la Fortuna |

| DINOTEC |

1 |

EBAR SAN GEOLIT Y AMP. EDAR MENGIBAR |

| DRACE MEDIOAMBIENTE |

1 |

EDAR EL ESPARTAL (MADRID) |

| FERROVIAL/AGROMAN |

5 |

Saneamiento Torrelodones |

| IOMSAL |

1 |

EDAR EL PASTEL Y EDAR LOS MOLINOS |

| JOCA |

6 |

EDAR'S ALMONACID (CUENCA) |

| MP SERVICIOS INDUSTRIALES |

1 |

Edar El Cuervo |

| SACYR |

1 |

Campus Boadilla |

| SPA |

1 |

Edar Venturada |

| SPA |

1 |

Edar Puebla de la Sierra |

| SPA |

1 |

Edar Lozoyuela |

| SPA |

1 |

Edar Gascones |

| UTE COLECTORES ARROYO QUIÑONES |

1 |

Ebar Arroyo Quiñones |

| UTE EDAR SAN BARTOLOME |

1 |

EDAR SAN BARTOLOME DE LA TORRE |

| UTE PAS-SPA |

1 |

Edar Arenas de San Pedro |

Filter sieves offer high performance in the solid-liquid separation process. Our range of equipment responds to the different possible needs for each case.

Band screens are those equipments, installed in a channel or , which has a series of filtering surfaces in continuous movement. Its mission is to extract the suspended solids of a certain size that accompany the effluent. There are several types of band screens, depending on the characteristics of the effluent and the installation:

The objective of this equipment is to protect the WWTP or pumping well from the possible arrival of large objects capable of causing obstructions in the different units of the installation. This operation consists of passing the waste water through a screen that separates and evacuates the bulky materials dragged along. They will retain large-sized solids such as branches, leaves, paper, tree roots, plastics, wipes, rags, etc., preventing damage and blockages to pumps, valves, pipes and other elements present in subsequent treatment processes of the purification plant.

These devices allow to continue filtering while performing self-cleaning, being especially suitable for those applications where continuous filtering is an important parameter of the process. Filtramas recommends the installation of its FB or FW in-line filters according to the flow and filtration needs.

Filter sieves offer high performance in the solid-liquid separation process. Our range of equipment responds to the different possible needs for each case.

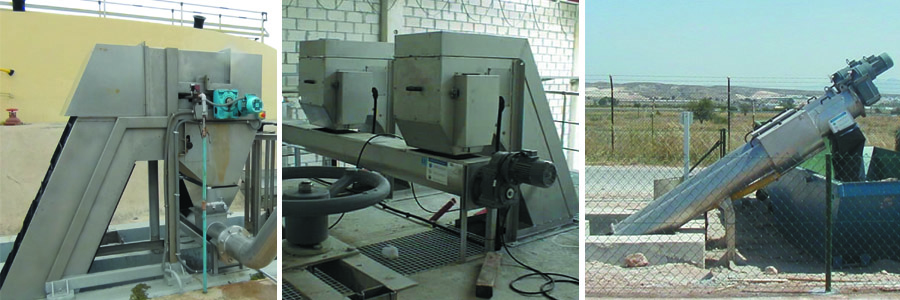

FILTRAMAS, S.A. has a wide range of solutions for the transport and compacting of the waste extracted by its machines, in a clean and discreet. The conveying and compacting systems can be with screws with final draining zone or hydraulic presses.

The conveyor-compactor screws supplied by FILTRAMAS, S.A., coupled together with its equipment, allow us to obtain a totally clean and fair-faced installation. The screw loading openings are designed for coupling to the discharge opening of the extraction equipment (bars movable grilles or screens), and the intermediate spaces are covered by a fairing.

In any water treatment or purification plant, there is a continuous need to isolate or regulate the flow of water in the channels and manholes or holes in walls (wall gates). This function is carried out by means of the placement of gates and cofferdams.

The result of our experience is the establishment of a standardization that determines a satisfactory result with a simple construction. For this reason, Filtramas has been developing the manufacture of penstocks and flashboards.

Filtramas manufactures channel hatches, wall hatches and cofferdams for different applications and uses.

The accumulation of solid waste in water treatment requires effective mechanized solutions for its extraction. FILTRAMAS, S.A. has a wide variety of equipment for the dragging of solid waste.

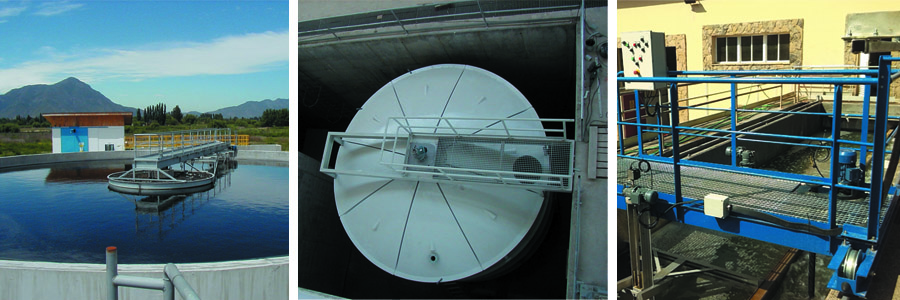

In the biological treatment of wastewater, a series of processes are generated based on the cultivation of bacterial microorganisms for the elimination of organic matter, nitrogen and phosphorus. It is one of the most common treatments for its simplicity and low cost.

FILTRAMAS, S.A. has a wide variety of equipment for bacterial culture applied to the treatment of urban and industrial wastewater.

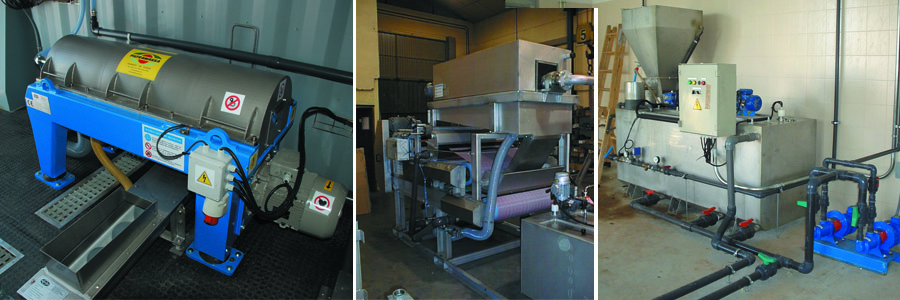

The dewatering of sludge is an essential process in the management of solid waste generated in water treatment. FILTRAMAS, S.A. offers different mechanized solutions to the problem according to the different possible needs.

FILTRAMAS S.A. has a wide variety of solutions for all kinds of problems associated with the treatment and cleaning of water, mud and sand. We develop our specialisation on the basis of the experience accumulated by our professionals, constant effort and close collaboration with our clients. FILTRAMAS S.A. perfects new products, looking for economic and effective solutions. Any problem that arises in the handling of fluids is carefully analyzed in order to find an economically balanced solution.