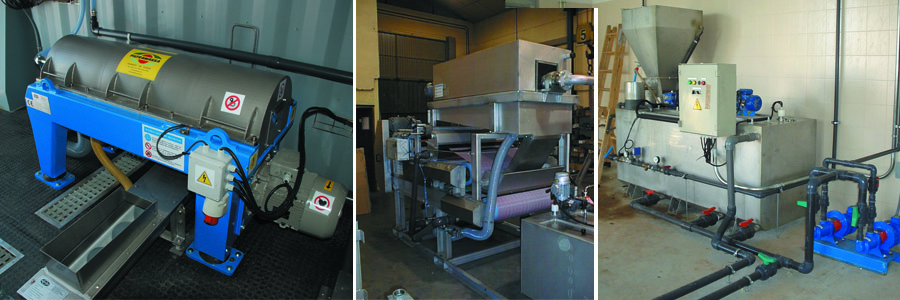

SLUDGE DEWATERING > CC Centrifugal Decanter

INTRODUCTION:

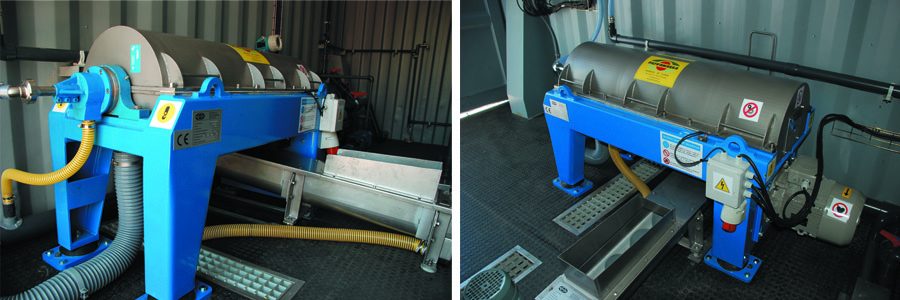

The CC centrifugal decanter is a simple, 2-stage configuration, specifically designed for the treatment of sludge from wastewater. The available qualities depend on the customer’s requirements.

The decanter can be driven either by a mechanical belt drive, which prints a constant relative speed to both the drum and the conveyor, or by a hydraulic transmission to the reducer shaft, which transmits the movement to the conveyou.

DESCRIPTION:

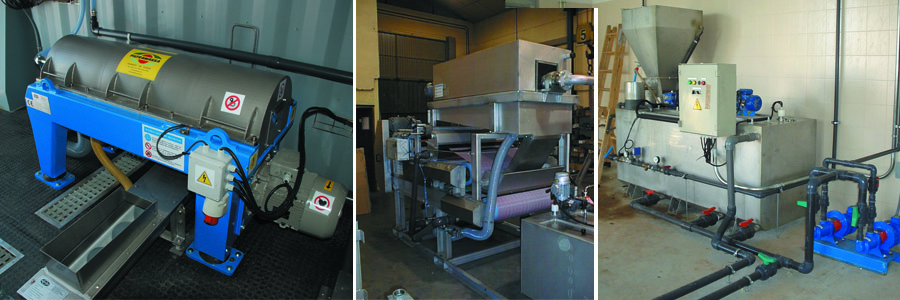

The FILTRAMAS centrifugal decanter is a simple configuration equipment designed to dehydrate the sludge coming from the treatment of the residual water, with a concentration variable between 1 and 6%. For an efficient separation, polyelectrolyte is dosed to achieve an adequate flocculation that allows us to separate both liquid and solid phases by centrifugation.

The operation is simple. The unit must be started by means of a frequency converter until the speed is reached. The poly and sludge pumps are then started and the flocculated mixture is fed through the inlet pipe.

Thanks to the centrifugal force, the liquid part forms a ring on the inside and the solid part adheres to the walls of the drum. The clarification is evacuated by means of concentric dumps, while the dehydrated sludge is dragged to the outlet where it exits at high speed.

The dryness thus obtained depends on the flow rate, the type of sludge, the initial concentration and the quantity, quality and characteristics of the polyelectrolyte used for flocculation.

The equipment consists of:

-

Drum. Built in stainless steel AISI 304. It has two areas, one cylindrical and the other conical trunk.

-

Screw conveyor. It is manufactured in AISI 304 stainless steel and tungsten carbide is added to the flanks to reinforce its anti-erosion capacity.

-

Drive unit. Electric motor that spins at 3000 rpm and transmits the movement by means of a set of pulleys that causes a differential speed between the drum and the worm that pulls the sludge towards the outlet.

-

Support structure. Manufactured in electrowelded and surface treated A42b carbon steel.

-

Supernatant collection tray. Made of AISI 304 stainless steel.

-

Cover hood. Made of AISI 304 stainless steel, open type and easy to dismantle, for easy access to the drum.

-

Accessories. Power and control panel controlled by a WEG variable speed drive with three-phase supply including programming of the entire process (pumps, agitators, polyelectrolyte preparation plant, washing solenoid valves, conveyor screw, etc).

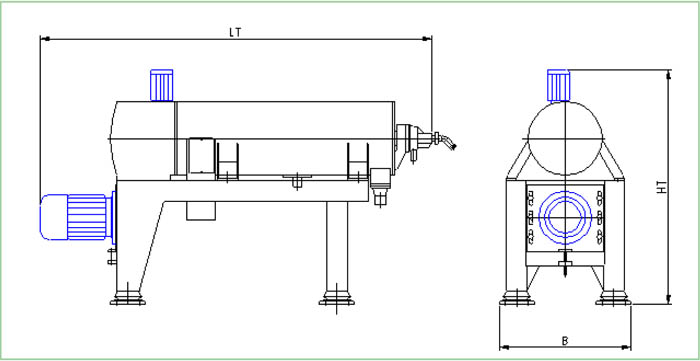

GENERAL DIMENSIONS:

The dewatering of sludge is an essential process in the management of solid waste generated in water treatment. FILTRAMAS, S.A. offers different mechanized solutions to the problem according to the different possible needs.

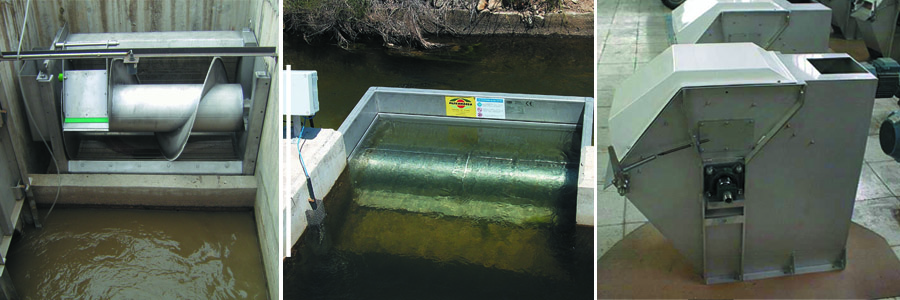

Band screens are those equipments, installed in a channel or , which has a series of filtering surfaces in continuous movement. Its mission is to extract the suspended solids of a certain size that accompany the effluent. There are several types of band screens, depending on the characteristics of the effluent and the installation:

The objective of this equipment is to protect the WWTP or pumping well from the possible arrival of large objects capable of causing obstructions in the different units of the installation. This operation consists of passing the waste water through a screen that separates and evacuates the bulky materials dragged along. They will retain large-sized solids such as branches, leaves, paper, tree roots, plastics, wipes, rags, etc., preventing damage and blockages to pumps, valves, pipes and other elements present in subsequent treatment processes of the purification plant.

These devices allow to continue filtering while performing self-cleaning, being especially suitable for those applications where continuous filtering is an important parameter of the process. Filtramas recommends the installation of its FB or FW in-line filters according to the flow and filtration needs.

Filter sieves offer high performance in the solid-liquid separation process. Our range of equipment responds to the different possible needs for each case.

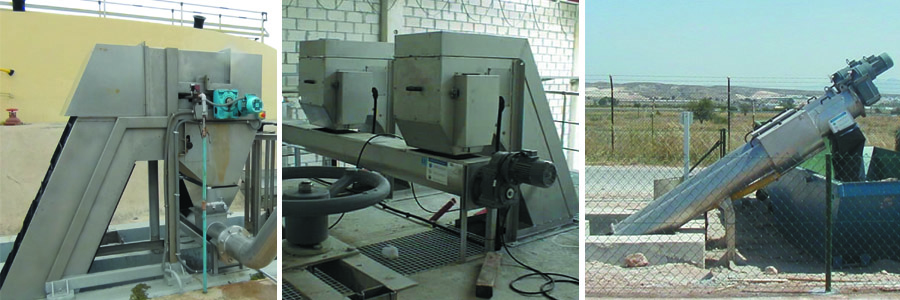

FILTRAMAS, S.A. has a wide range of solutions for the transport and compacting of the waste extracted by its machines, in a clean and discreet. The conveying and compacting systems can be with screws with final draining zone or hydraulic presses.

The conveyor-compactor screws supplied by FILTRAMAS, S.A., coupled together with its equipment, allow us to obtain a totally clean and fair-faced installation. The screw loading openings are designed for coupling to the discharge opening of the extraction equipment (bars movable grilles or screens), and the intermediate spaces are covered by a fairing.

In any water treatment or purification plant, there is a continuous need to isolate or regulate the flow of water in the channels and manholes or holes in walls (wall gates). This function is carried out by means of the placement of gates and cofferdams.

The result of our experience is the establishment of a standardization that determines a satisfactory result with a simple construction. For this reason, Filtramas has been developing the manufacture of penstocks and flashboards.

Filtramas manufactures channel hatches, wall hatches and cofferdams for different applications and uses.

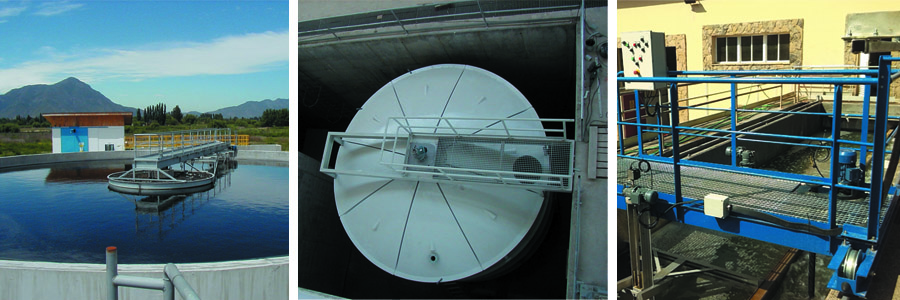

The accumulation of solid waste in water treatment requires effective mechanized solutions for its extraction. FILTRAMAS, S.A. has a wide variety of equipment for the dragging of solid waste.

In the biological treatment of wastewater, a series of processes are generated based on the cultivation of bacterial microorganisms for the elimination of organic matter, nitrogen and phosphorus. It is one of the most common treatments for its simplicity and low cost.

FILTRAMAS, S.A. has a wide variety of equipment for bacterial culture applied to the treatment of urban and industrial wastewater.

The dewatering of sludge is an essential process in the management of solid waste generated in water treatment. FILTRAMAS, S.A. offers different mechanized solutions to the problem according to the different possible needs.

FILTRAMAS S.A. has a wide variety of solutions for all kinds of problems associated with the treatment and cleaning of water, mud and sand. We develop our specialisation on the basis of the experience accumulated by our professionals, constant effort and close collaboration with our clients. FILTRAMAS S.A. perfects new products, looking for economic and effective solutions. Any problem that arises in the handling of fluids is carefully analyzed in order to find an economically balanced solution.