VARIOUS > CT Sand Sorter

INTRODUCTION:

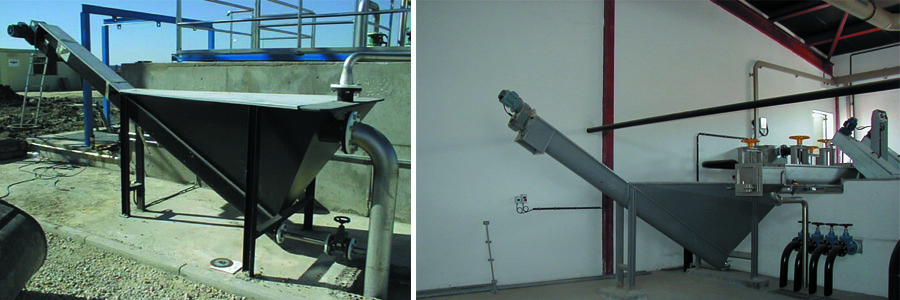

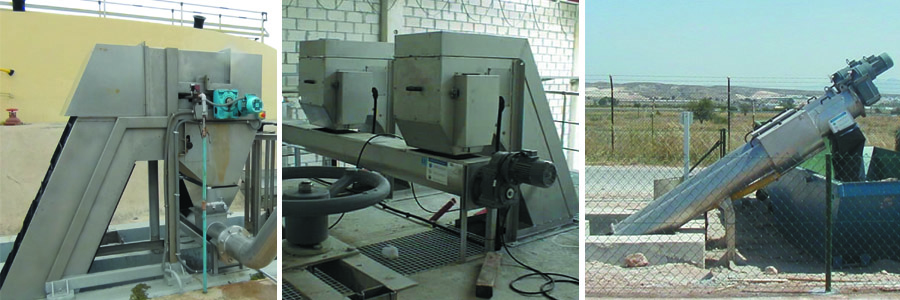

The sand sorting unit CT FILTRAMAS is a compact unit, of the conveyor screw type, designed for the separation and washing of sand.

The separation of the sand carried by the wastewater is essential to protect the rest of the installation and the equipment. Optimum separation of the sands prevents operating problems as well as their accumulation at different points in the process, abrasion on the mechanical equipment and possible clogging of the pipes.

DESCRIPTION:

The sand classifier model CT consists of the following elements:

- Concentration tank with outlet spillway.

- Sand lifting screw, with an inclination of about 30º approx.

-

Drive group.

The conveyor screw of the classifier slowly lifts the sands to the discharge level, allowing them to be drained off. The smooth movement of the propeller also causes the suspension of the organic matter, which has a density close to that of the water, to be discharged into the outlet spillway. In this way, a washing effect is achieved on the sands and a final product without too many odours.

The mixture of waste water and sand is introduced through the back of the classifier. Transversally, there is a spillway that maintains a constant level inside the equipment and provides an adequate circulation speed to cause the sedimentation of sands with a certain minimum granulometry and the dragging of organic matter.

The conveyor screw of the classifier slowly lifts the sands to the discharge level, allowing them to be drained off. The gentle movement of the propeller also causes the suspension of the organic matter contained, of a similar density to that of water, and which is dragged towards the outlet spillway; in this way, a washing effect is achieved on the sands and an almost odourless end product.

The classifier drive unit consists of a gearmotor located at the top of the classifier, which directly attacks the conveyor screw shaft. The unit must be protected by a shaft power monitor.

The sand elevator screw conveyor consists of a tubular drive shaft and welded coils of suitable thickness. The containment tank is made of corrosion-protected carbon steel plate or stainless steel, with removable panels on top.

The unit is fully enclosed and complies with the Machinery Safety Directive 98/392/EEC and its amendments (currently mandatory), as there are no moving parts without protection.

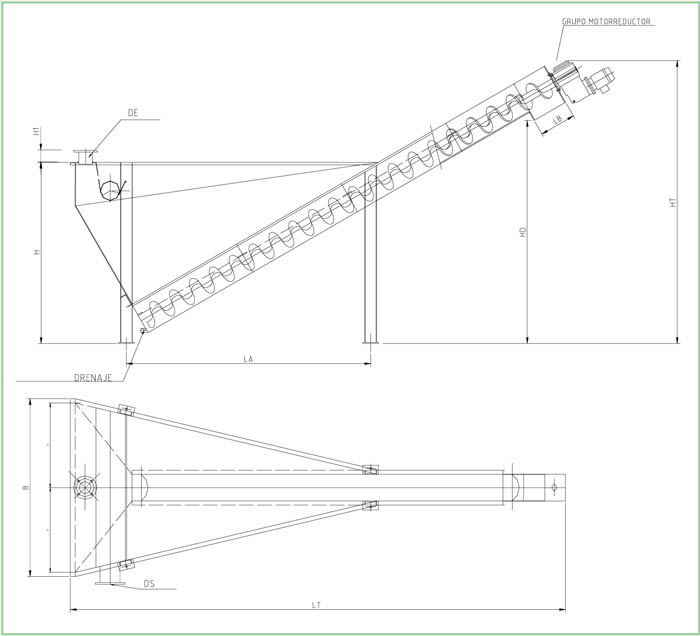

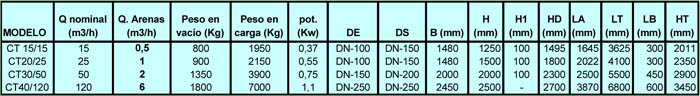

GENERAL DIMENSIONS:

|

CLIENTE / CUSTOMER |

CANT./QTY |

PROYECTO / PROJECT |

| ABENSUR |

1 |

EDAR Los Villares |

| ABENSUR |

1 |

EDAR Vellón, Molar y Pedrezuela |

| ACCIONA AGUA |

1 |

PLAN ESPECIAL DE DEP DE ARAGON |

| ACCIONA AGUA |

1 |

EDAR VILLAROBLEDO |

| ACCIONA AGUA |

1 |

ETAR CACIA |

| ACSA |

1 |

Colector Puleva |

| AGUAS DEL TELDE |

1 |

EDAR HOYA DEL POZO |

| ALCEDAR |

1 |

Alcorisa |

| ASTEISA |

1 |

Ribadeo |

| ASTEISA |

1 |

Valencia de Alcántara |

| ASTEISA |

1 |

Verín/Orense |

| CADAGUA |

1 |

Mejora EDAR Guia-Gal |

| CANAL ISABEL II |

1 |

COLMENAR VIEJO (MADRID) |

| CONSTRUCCIONES SARRION |

2 |

EDAR'S Calatrava |

| CONSTRUCCIONES SARRION |

1 |

EDAR LA SAGRA |

| COVIMAN - VINUMAR |

1 |

|

| DEGREMONT |

1 |

EDAR Vinaroz |

| DEGREMONT |

1 |

EDAR ORDUÑA |

| DEMAIN |

1 |

EDAR ESTEIRO-MUROS |

| DHVCEM |

1 |

ETAR Minde e Mira d’Aire |

| DINOTEC |

1 |

EDAR SATOCAN (LAS PALMAS DE GRAN CANARIA) |

| DINOTEC |

1 |

EDAR IZNALLOZ |

| DINOTEC |

1 |

MEJORA 7 DEPURADORAS - LAS PALMAS |

| DRACE MEDIOAMBIENTE |

1 |

EDAR ROBLEDILLO |

| DRACE MEDIOAMBIENTE |

1 |

EDAR BERZOSA |

| DRAGADOS |

1 |

CP ESTREMERA |

| DTD |

1 |

COLECTOR Y EDAR DE ALOSNO / HUELVA |

| DTD |

1 |

EDAR CASTELLAR DE LA FRONTERA Y ALMORAIMA |

| DYTRAS |

1 |

Fonsagrada |

| DYTRAS |

1 |

Olvera |

| DYTRAS |

2 |

EDAR Jerez de la Frontera |

| DYTRAS |

2 |

--- |

| DYTRAS |

1 |

EDAR de Jabugo |

| DYTRAS |

1 |

EDAR Fuenmayor |

| DYTRAS, S.A. |

2 |

Olvera Norte/Cádiz |

| DYTRAS, S.A. |

1 |

La Barca de la Florida/Jerez |

| DYTRAS |

1 |

EDAR ALAMEDA (MALAGA) |

| ECOPRENEUR CHILE |

1 |

|

| EPTISA |

1 |

EDAR CUIÑA |

| ETAP COLMENAR |

1 |

EDAR Colmenar |

| FACSA |

1 |

EDAR ALEDO (MURCIA) |

| FCC CONSTRUCCION |

1 |

AMPLIACION EDAR CAMPO REAL |

| FERROVIAL-AGROMAN |

1 |

EDAR Alcantarilla |

| GIA GRUPO EP |

1 |

EDAR Briviesca |

| GRUPO GENERALA |

1 |

HACIENDA RIQUELME |

| HLC |

1 |

EDAR en Portugal |

| IMFLUID |

1 |

EDAR Algarrobo |

| IMFLUID |

1 |

EDAR EN PORTUGAL |

| IMFLUID |

1 |

EDAR POL. JUNCARIL-ASEGRA ALBOLOTE (GRANADA) |

| INITEK INGENIEROS |

1 |

EDAR NANCLARES |

| ISOLUX WAT |

1 |

C.P. Dueñas |

| ISOLUX WAT |

1 |

EDAR Villaconejos |

| ISOLUX WAT |

1 |

EDAR Calasparra |

| MANCHA REAL UTE |

1 |

EDAR MANCHA REAL |

| M.JOCA |

1 |

EDAR Valdelacalzada |

| MEYDE |

1 |

EDAR´S PUEBLOS DE GRANADA |

| MP SERVICIOS INDUSTRIALES |

1 |

EDAR DE EL CUERVO |

| NOCHE Y DIA |

1 |

Bullas |

| NOCHE Y DIA |

1 |

Alcantarillas |

| NUFRI |

1 |

EDAR MOLLERUSA (LLEIDA) |

| OBRASQUALIA FOR CONSTRUCTIONS |

2 |

NEW CAIRO - EGYPTO |

| OCIDE CONSTRUCCIONES SA |

1 |

EDAR ALBAIDA |

| ORTIZ CONSTRUCCIONES |

1 |

Edar Cobeña |

| PASSAVANT ESPAÑA |

1 |

EDAR BAIONA (PONTEVEDRA) |

| PASSAVANT-COPASA |

1 |

EMISARIO Y EDAR VILLABRAZARO (ZAMORA) |

| PRIDESA |

1 |

Es-Mitjorn |

| PRIDESA |

1 |

EDAR Puente Genil |

| PRIDESA |

1 |

EDAR Cehegín |

| PRIDESA |

1 |

EDAR Tanger |

| PRIDESA |

1 |

EDAR Herencia |

| RIEGOSUR |

1 |

EDAR Carmona |

| SADYT |

1 |

EDAR BURGUILLOS |

| SADYT |

1 |

EDAR POLAN |

| SAICO |

1 |

Tavernes |

| SITEL |

1 |

ETAR Arruda Dos Vinhos |

| SOCAMEX |

1 |

C.P. Alama. |

| SOCAMEX |

1 |

EDAR Soller |

| SOCAMEX |

1 |

EDARI CAMPOFRIO |

| SPA |

1 |

EDAR Callosa |

| TAESA |

1 |

--- |

| TECNICAS REUNIDAS |

1 |

EDAR CAÑADA DE GALLEGO T.M. MAZARRON (MURCIA) |

| TECYMED |

1 |

EDAR Masia Baló |

| TECYMED |

1 |

EDAR Nova Panorámica Sant Jordi |

| TRITIO |

2 |

EDAR CP TOPAS |

| TRITIO |

1 |

EDAR CP VALLADOLID |

| U.T.E. COLLOSA-SOCAMEX |

1 |

EDAR ASTORGA (LEON) |

| UC-10 - DINOTEC |

1 |

EDAR TORREPEROGIL |

| UTE ABASTECIMIENTO PUERTOLLANO |

1 |

EDAR PUERTOLLANO - CIUDAD REAL |

| UTE AMPLIACIÓN DE ARANJUEZ |

1 |

EDAR Aranjuez |

| UTE CONSTRUCTORA PEACHE |

1 |

EDAR MATAPOZUELOS |

| UTE EDAR ARROYO LA REGUERA |

1 |

Cuenca del Arroyo de la Reguera |

| UTE EDAR BOADILLA (FCC-SPA) |

1 |

EDAR Boadilla del Monte |

| UTE EDAR OSUNA |

1 |

EDAR OSUNA |

| UTE EDAR SAN BARTOLOME |

1 |

EDAR SAN BARTOLOME DE LA TORRE |

| UTE EDAR TALAVERA |

1 |

AMPLIACION EDAR TALAVERA DE LA REINA |

| UTE EDAR VALLS |

1 |

EDAR Valls |

| UTE PRIDESA-GRAMAN |

1 |

EDAR Borja |

| UTE UICESA DHA |

1 |

EDAR CENTRO PENITENCIARIO ALBOCASSER |

| UTEDAR |

1 |

EDAR Huesca |

FILTRAMAS S.A. has a wide variety of solutions for all kinds of problems associated with the treatment and cleaning of water, mud and sand. We develop our specialisation on the basis of the experience accumulated by our professionals, constant effort and close collaboration with our clients. FILTRAMAS S.A. perfects new products, looking for economic and effective solutions. Any problem that arises in the handling of fluids is carefully analyzed in order to find an economically balanced solution.

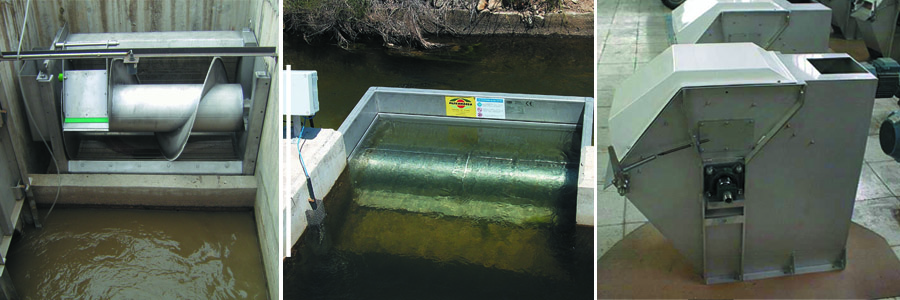

Band screens are those equipments, installed in a channel or , which has a series of filtering surfaces in continuous movement. Its mission is to extract the suspended solids of a certain size that accompany the effluent. There are several types of band screens, depending on the characteristics of the effluent and the installation:

The objective of this equipment is to protect the WWTP or pumping well from the possible arrival of large objects capable of causing obstructions in the different units of the installation. This operation consists of passing the waste water through a screen that separates and evacuates the bulky materials dragged along. They will retain large-sized solids such as branches, leaves, paper, tree roots, plastics, wipes, rags, etc., preventing damage and blockages to pumps, valves, pipes and other elements present in subsequent treatment processes of the purification plant.

These devices allow to continue filtering while performing self-cleaning, being especially suitable for those applications where continuous filtering is an important parameter of the process. Filtramas recommends the installation of its FB or FW in-line filters according to the flow and filtration needs.

Filter sieves offer high performance in the solid-liquid separation process. Our range of equipment responds to the different possible needs for each case.

FILTRAMAS, S.A. has a wide range of solutions for the transport and compacting of the waste extracted by its machines, in a clean and discreet. The conveying and compacting systems can be with screws with final draining zone or hydraulic presses.

The conveyor-compactor screws supplied by FILTRAMAS, S.A., coupled together with its equipment, allow us to obtain a totally clean and fair-faced installation. The screw loading openings are designed for coupling to the discharge opening of the extraction equipment (bars movable grilles or screens), and the intermediate spaces are covered by a fairing.

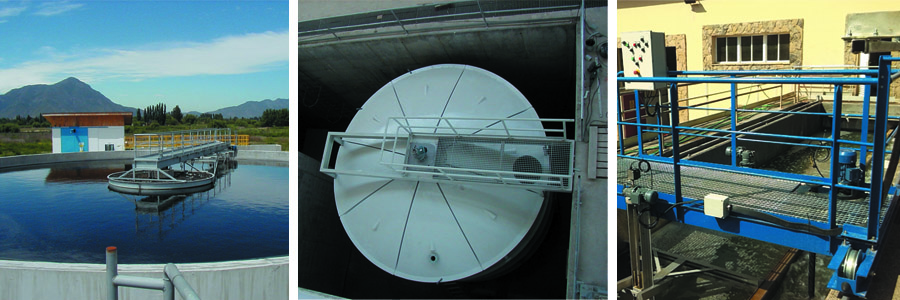

In any water treatment or purification plant, there is a continuous need to isolate or regulate the flow of water in the channels and manholes or holes in walls (wall gates). This function is carried out by means of the placement of gates and cofferdams.

The result of our experience is the establishment of a standardization that determines a satisfactory result with a simple construction. For this reason, Filtramas has been developing the manufacture of penstocks and flashboards.

Filtramas manufactures channel hatches, wall hatches and cofferdams for different applications and uses.

The accumulation of solid waste in water treatment requires effective mechanized solutions for its extraction. FILTRAMAS, S.A. has a wide variety of equipment for the dragging of solid waste.

In the biological treatment of wastewater, a series of processes are generated based on the cultivation of bacterial microorganisms for the elimination of organic matter, nitrogen and phosphorus. It is one of the most common treatments for its simplicity and low cost.

FILTRAMAS, S.A. has a wide variety of equipment for bacterial culture applied to the treatment of urban and industrial wastewater.

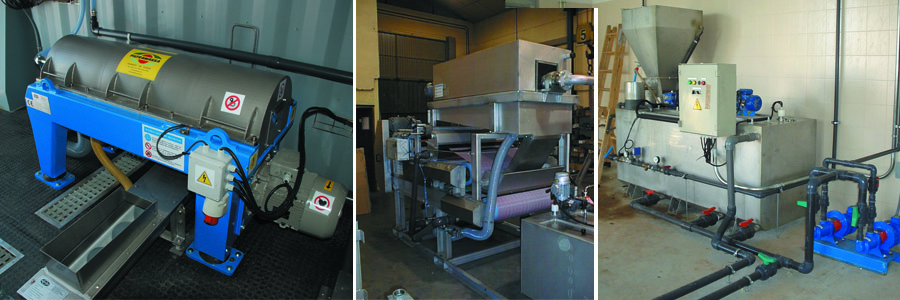

The dewatering of sludge is an essential process in the management of solid waste generated in water treatment. FILTRAMAS, S.A. offers different mechanized solutions to the problem according to the different possible needs.

FILTRAMAS S.A. has a wide variety of solutions for all kinds of problems associated with the treatment and cleaning of water, mud and sand. We develop our specialisation on the basis of the experience accumulated by our professionals, constant effort and close collaboration with our clients. FILTRAMAS S.A. perfects new products, looking for economic and effective solutions. Any problem that arises in the handling of fluids is carefully analyzed in order to find an economically balanced solution.