BIOLOGICAL TREATMENT > Depurblock Compact Plant

INTRODUCTION:

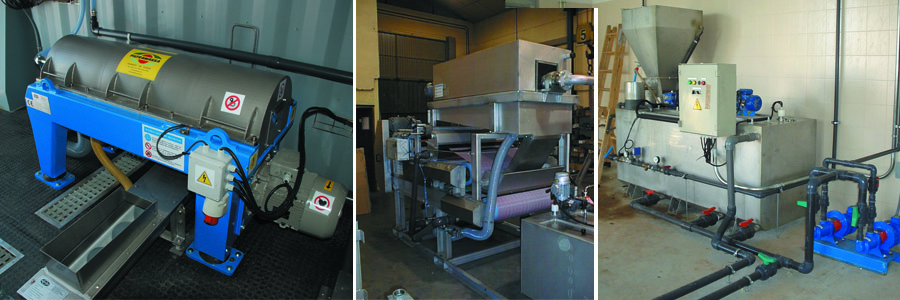

Compact DEPURBLOCK plants in Filtramas are based on the Biodisc purification system and offer a very stable purification process that does not require any auxiliary control. The absorption produced is similar to that obtained with bacterial or submerged bed processes, with the advantage, in the case of biodiscs, that there are concatenated stages that provide greater performance.

DESCRIPTION:

The compact DEPURBLOCK plant is suitable for the treatment of wastewater from towns of less than 1000 inhabitants and can also be used for the treatment of any biodegradable waste.

The DEPURBLOCK compact plant usually consists of the following processes:

- Pretreatment with a self-cleaning sieve.

- Primary decanter with digestion/sludge storage chamber.

- ROTOSPIR rotary biological contactor with feeder.

-

Secondary decanter with continuous sludge recirculation system to digestion/storage chamber.

The process begins with the sieving of the effluent and subsequent primary decanting to remove a large amount of solids and part of the BOD fraction5. The sludge from the decanting process is taken to digestion.

The influent is then treated in the SIDECA (patented adhered culture denitrification system) together with a recirculation of water from the biodisc outlet with a high nitrate content. With this anoxic process, biological denitrification is achieved.

The next step is the aerobic biological treatment inside the biodiscs and then a secondary decanting, not before recirculating a fraction of the flow to the headwater and removing the nitrogen contained in the nitrates.

At this point the sludge is separated from the treated effluent leaving the plant by overflowing. In addition, the secondary decanter incorporates a lamella system that allows the decanter to increase the ascending speed values.

The degree of purification obtained depends on the characteristics of the inlet flow rate and the number of biological stages installed. The optimum performance of the biological unit is achieved after several weeks of continuous operation, when the bacterial population of the biodisc has proliferated.

The sludge produced is discharged to the storage tank. There, the stored sludge is concentrated, experiencing cold anaerobic digestion.

The DEPURBLOCK compact plant has the following FEATURES:

-

Robust, reliable and extensively tested, it works in a totally reliable way autonomous.

-

The bacterial population is automatically self-regulating depending on the working conditions.

-

There is no need for specialized personnel to control the process, as is the case with the recirculation of sludge in the activated sludge system.

-

The plant allows the accumulation of sludge over a period of several weeks.

-

The extracted sludge is very stable, acquires very high concentrations and allows its evacuation by means of a tanker truck without any difficulty.

-

The equipment can be supplied as a complement to a septic tank at the head of the unit or with a built-in storage system.

GENERALE DIMENSIONS:

|

CLIENTE / CUSTOMER |

CANT./QTY |

PROYECTO / PROJECT |

| DIPUTACION CASTELLÓN |

1 |

EDAR'S LUDIENTES Y VILLAR DE CANES |

| DYTRAS |

1 |

EDAR VILLANUEVA DEL ROSARIO (MALAGA) |

| INITEK |

2 |

EDAR VALDEGOVIA |

| TECVASA |

1 |

EDAR LORIGUILLA |

| PASSAVANT ESPAÑA S.A. |

2 |

EDAR SMOLIAN (BULGARIA) |

| PASSAVANT ESPAÑA S.A. |

1 |

EDAR SOLIVELLA |

| SOCAMEX |

1 |

EDAR EL CARPIO |

| UTE LUMBRALES |

1 |

UTE LUMBRALES |

| UTE SOCAMEX-JUAN NICOLAS GOMEZ E HIJOS |

5 |

EDAR'S GUADALAJARA |

In the biological treatment of wastewater, a series of processes are generated based on the cultivation of bacterial microorganisms for the elimination of organic matter, nitrogen and phosphorus. It is one of the most common treatments for its simplicity and low cost.

FILTRAMAS, S.A. has a wide variety of equipment for bacterial culture applied to the treatment of urban and industrial wastewater.

Band screens are those equipments, installed in a channel or , which has a series of filtering surfaces in continuous movement. Its mission is to extract the suspended solids of a certain size that accompany the effluent. There are several types of band screens, depending on the characteristics of the effluent and the installation:

The objective of this equipment is to protect the WWTP or pumping well from the possible arrival of large objects capable of causing obstructions in the different units of the installation. This operation consists of passing the waste water through a screen that separates and evacuates the bulky materials dragged along. They will retain large-sized solids such as branches, leaves, paper, tree roots, plastics, wipes, rags, etc., preventing damage and blockages to pumps, valves, pipes and other elements present in subsequent treatment processes of the purification plant.

These devices allow to continue filtering while performing self-cleaning, being especially suitable for those applications where continuous filtering is an important parameter of the process. Filtramas recommends the installation of its FB or FW in-line filters according to the flow and filtration needs.

Filter sieves offer high performance in the solid-liquid separation process. Our range of equipment responds to the different possible needs for each case.

FILTRAMAS, S.A. has a wide range of solutions for the transport and compacting of the waste extracted by its machines, in a clean and discreet. The conveying and compacting systems can be with screws with final draining zone or hydraulic presses.

The conveyor-compactor screws supplied by FILTRAMAS, S.A., coupled together with its equipment, allow us to obtain a totally clean and fair-faced installation. The screw loading openings are designed for coupling to the discharge opening of the extraction equipment (bars movable grilles or screens), and the intermediate spaces are covered by a fairing.

In any water treatment or purification plant, there is a continuous need to isolate or regulate the flow of water in the channels and manholes or holes in walls (wall gates). This function is carried out by means of the placement of gates and cofferdams.

The result of our experience is the establishment of a standardization that determines a satisfactory result with a simple construction. For this reason, Filtramas has been developing the manufacture of penstocks and flashboards.

Filtramas manufactures channel hatches, wall hatches and cofferdams for different applications and uses.

The accumulation of solid waste in water treatment requires effective mechanized solutions for its extraction. FILTRAMAS, S.A. has a wide variety of equipment for the dragging of solid waste.

In the biological treatment of wastewater, a series of processes are generated based on the cultivation of bacterial microorganisms for the elimination of organic matter, nitrogen and phosphorus. It is one of the most common treatments for its simplicity and low cost.

FILTRAMAS, S.A. has a wide variety of equipment for bacterial culture applied to the treatment of urban and industrial wastewater.

The dewatering of sludge is an essential process in the management of solid waste generated in water treatment. FILTRAMAS, S.A. offers different mechanized solutions to the problem according to the different possible needs.

FILTRAMAS S.A. has a wide variety of solutions for all kinds of problems associated with the treatment and cleaning of water, mud and sand. We develop our specialisation on the basis of the experience accumulated by our professionals, constant effort and close collaboration with our clients. FILTRAMAS S.A. perfects new products, looking for economic and effective solutions. Any problem that arises in the handling of fluids is carefully analyzed in order to find an economically balanced solution.